We strictly follow the operating requirements of the ISO9001 quality system and adopt standardized management in product design, procurement, construction and other links.It is committed to the design and development of metal porous materials, filter elements, and also the filtration and separation equipment.

Get Started with a Free Quote for

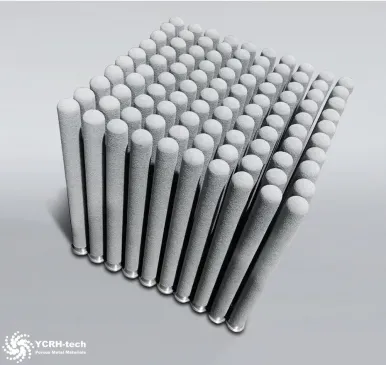

Microporous Metal Membrane Elements

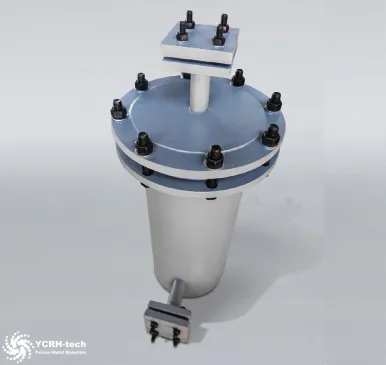

and A Solution Related Filtration and Separation Systems